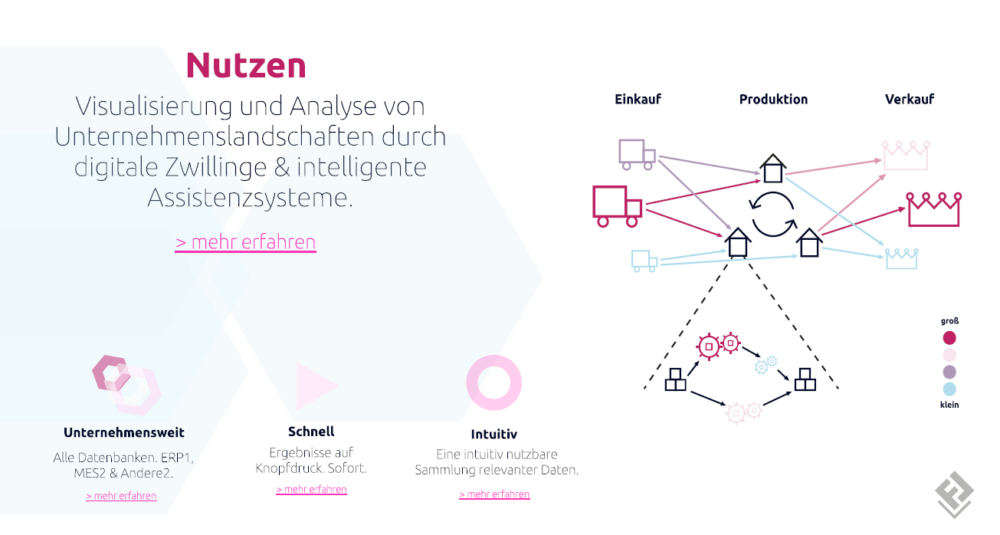

Companies collect an enormous amount of data about their processes along the entire value chain from supply chain, production and logistics to customers. Nevertheless, there is often a lack of a “big picture”, an overview of all processes, in order to identify problems, waste and potential at an early stage. Such a big picture makes the interdependencies transparent as a whole and at the same time ensures that they can be recorded much more accurately. This would allow a considerable part of the potential that lies dormant in this data to be put to additional use. Mauritius Geiger from fLUMINA GmbH advocated this position in his online lecture “Data-based value stream analysis” on November 5 as part of the ESSC-D’s online lecture series. “The aim should be to create an automatic value stream analysis from existing company data at the touch of a button. With the right technology, this can be done within a few minutes and without a great deal of effort,” says Mauritius Geiger. However, this dream does not come for free. This is because the data systems need to be connected and structured accordingly. “Until they have seen it for themselves, many customers don’t believe that this can sometimes be done within hours,” says Mauritius Geiger.

The online lecture series is very popular with Six Sigma experts and members of the ESSC-D. “We are delighted with the forward-looking topics on the pulse of the times, which keep our network together and even expand it, especially in uncertain times,” says Michael Ohler from the Six Sigma Club Board. The next event in the lecture series on December 21 will focus on “Human Time Management” with speakers Gudmundur Smarason and Anders Rasmussen. They will be looking in depth at the main reasons why projects and tasks are not completed and how this can be effectively improved. Their program is already proving successful in pilot companies.

Press release as PDF:

Data-based value stream mapping