Digitization is creating a new, unprecedented availability of data. This means that more data, both structured and unstructured, is available from an increasing number of sources of varying quality. This is changing the approach to data-supported problem solving and process improvement and therefore also Six Sigma. In the past, the focus was on the project-related collection of the right data to solve a problem. Today, on the other hand, it is increasingly a question of efficiently selecting the relevant data from large quantities of existing data and achieving the best possible result.

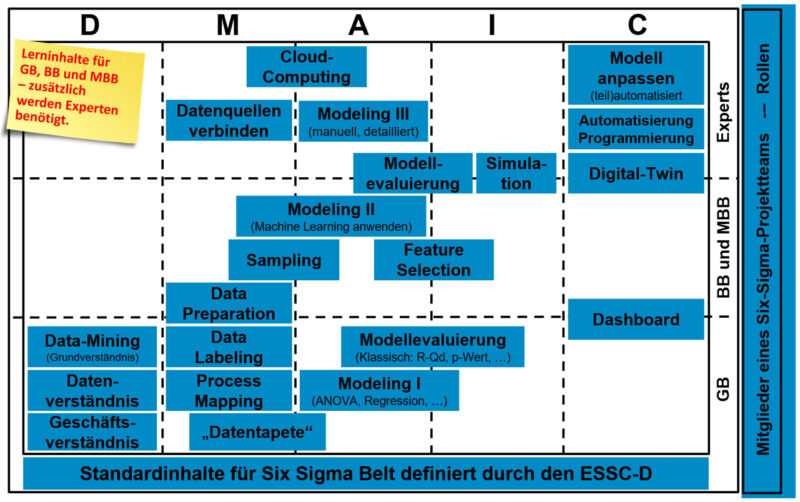

In order to take this development into account, it is necessary to expand the Six Sigma toolbox in the direction of data sciences, in particular big data, data mining and machine learning. To this end, the proven Six Sigma training must be supplemented. A corresponding approach has now been developed in the ESSC-D working group “Six Sigma Weitergedacht”. Based on the experience gained from numerous projects and training courses, the effects of digitalization and big data on the tried-and-tested Six Sigma process improvement method were discussed. Various research projects from the universities involved in the ESSC-D and results from workshops at the ESSC-D specialist conferences were incorporated into this process. “We are delighted that we can now use the extended training approach to provide our method experts with the necessary skills in a short space of time with a good depth of knowledge,” says Björn Noreik from the Executive Board of the Six Sigma Club.

The new approach has been summarized in a training guideline, which can be found on the Six Sigma Club website (www.sixsigmaclub.de). Training dates for interested parties are also posted there.

Press release as PDF:

Data Mining for Six Sigma Belts